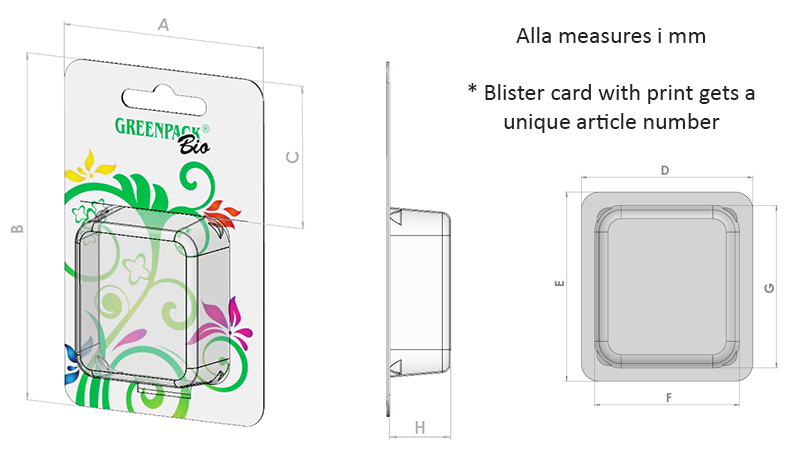

GREENPACK Bio, Safe & Slide

These solutions are based on printed and punched cards with a flap in the front wherein the blister is placed. The card is then folded around the blister. The sealing is done by pressing and heating the two cardboard halves around the blister. High percentage of renewable raw material (cardboard) and partially recycled PET or BIO-PET makes this a truely environment friendly alternative.

All printing on one side, which gives lower start-up and production costs compared to double-sided printing. This packaging solution offers great potential for attractive and unique design

Greenpack Bio - New!

Less Plastics

Bio-materials

Renewable

Easy to Separate and Recycle

Greenpack Bio is our standard blister solution for this blister packaging type. A packaging solution that reduces plastic consumption by an average of 70% compared to the corresponding size of traditional clamshell blister. Blister is made from BIO-PET which has 30% plant-based raw material. Blister card made of renewable cardboard. The entire package is 100% recyclable.

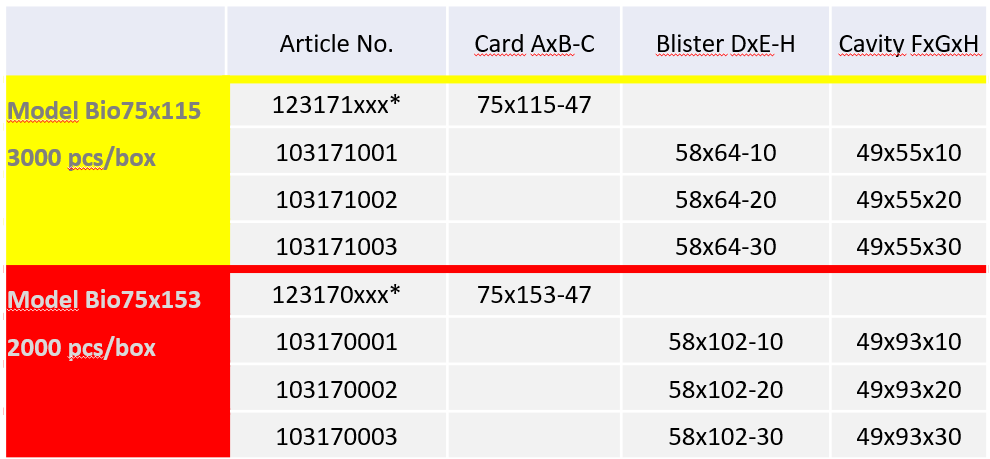

No tooling costs for molds and punching tools for our standard packages in the list!

GREENPACK Bio has an opening function where the upper part is folded back and blister can be pulled out.

When closing, place the blister in the punched socket in one half of the card. The card is folded around the blister and sealed in a suitable packaging machine such as GP310S and GP2000.

Greenpack Bio - Standardmodeller

Greenpack Safe

Design without opening function makes it tamper proof. Totally safe!

Greenpack Slide

A flap on to p of the blister bubble makes it possible to open and re-seal. A warranty sealing can easily be integrated during packaging..

The punched flap at the card front enables using blisters with infinite number of shapes with the same card format.

- Logistics advantages

- Great overall economies

- Print also behind blister and product